-40%

Renishaw MCG Machine Checking Gauge For CMM Calibration & Verification

$ 475.19

- Description

- Size Guide

Description

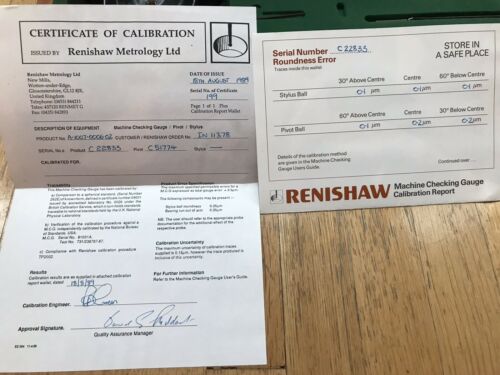

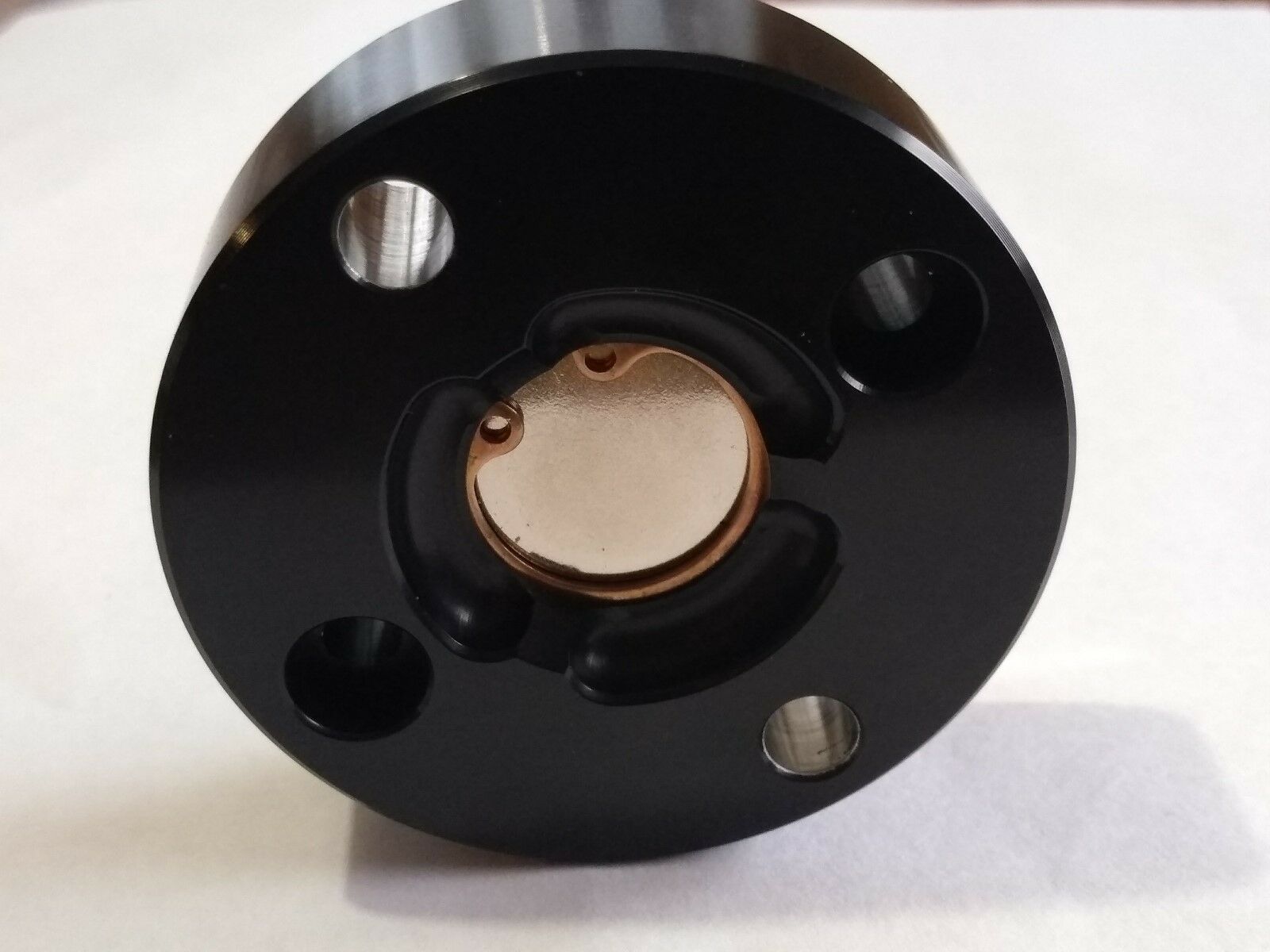

Fully Tested Renishaw MCG Machine Checking Gage CMM Calibration Standard in original foam lined mahogany box.Renishaw Machine Checking Gage is in excellent condition!

Machine Checking Gauge (MCG) for CMM performance monitoringMost CMM's are typically subjected to an annual service and re-calibration by the original equipment manufacturer (OEM) or independent calibration service. Testing is often carried out to a defined procedure laid down in a recognised standard such as ISO, ASME, or VDI/VDE. These tests require the use of fixed length ball-ended bars or step gauges and laser measurement systems (e.g Renishaw XL-80 laser). The measurement data can then be used to modify the CMM controller's electronic error map to restore it to within accuracy specifications. This well recognised procedure is essential but can be time consuming and costly.

Many end users want a simpler method of monitoring accuracy at regular intervals between these checks, or after a collision. Using the Renishaw MCG, they are able to carry out a (typically) 10-20 minute interim verification of volumetric accuracy to ISO 10360-2. The results give assurance that measurements taken on the CMM are accurate, or give conclusive proof that servicing or re-calibration work is needed. The process is quick and cost effective and a range of pillar heights and arm lengths mean that volumetric accuracy can be checked on both large and small CMMs.

Machine Checking Gauge

Checking time for CNC (DCC) Machine: typically 15 minutes

Checking time for joy-stick and manual machines: typically 45 minutes

Measuring range: vertical, ± 45°; horizontally, 360°

Total Gauge error: ±0.5µm

MCG 1 for Small Kit Machines up to 1m³

MCG 2 for Comprehensive Kit Machines greater than 1m³

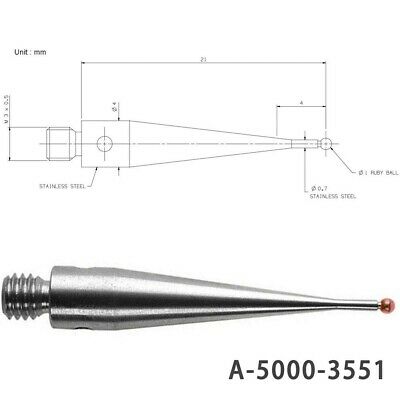

The probe stylus slots into the end of what is in effect a reference "ball" bar. The probe carries the bar with it over a spherical path, and radial readings are taken at different positions. The range of these radial readings indicates the Volumetric Measuring Performance of the machine. Repetition of a sequence of readings checks the system repeatability.

Volumetric Measuring Performance is the maximum error between any two points in any plane, over any distance within the full measuring volume.

Calibration traceable to USA National Institute of Standards and Technology (Ref # 731/23897-87). The Machine Checking Gauge also complies with British Standard BS6808: Co-ordinate Measuring Machines.

Machine Checking Gauge For CMM. Condition is "Used".