-40%

Commercial Automatic pasta noodle making machine, fresh Noodle Maker 220V t

$ 704.35

- Description

- Size Guide

Description

Commercial Automatic pasta noodle making machine, fresh Noodle Maker1 year warranty

instructions:

Introduction

The machine has small volume, high efficiency, convenient movement and easy to remove, the machine use 220 v single-phase motor, suitable for collective canteens, hotels, and small vermicelli processing plants, improve the work efficiency to reduce the labor intensity.

Specifications

Voltage:

220v/50Hz

Power:2.5kw

Rotate Speed:1400r/min

Diameter:78mm

Production speed:2 bowl/ 10 second

Net Weight:53kg

Gross Weight:75KG

Size:63cm*20cm*70cm(LxWxH)

Feature

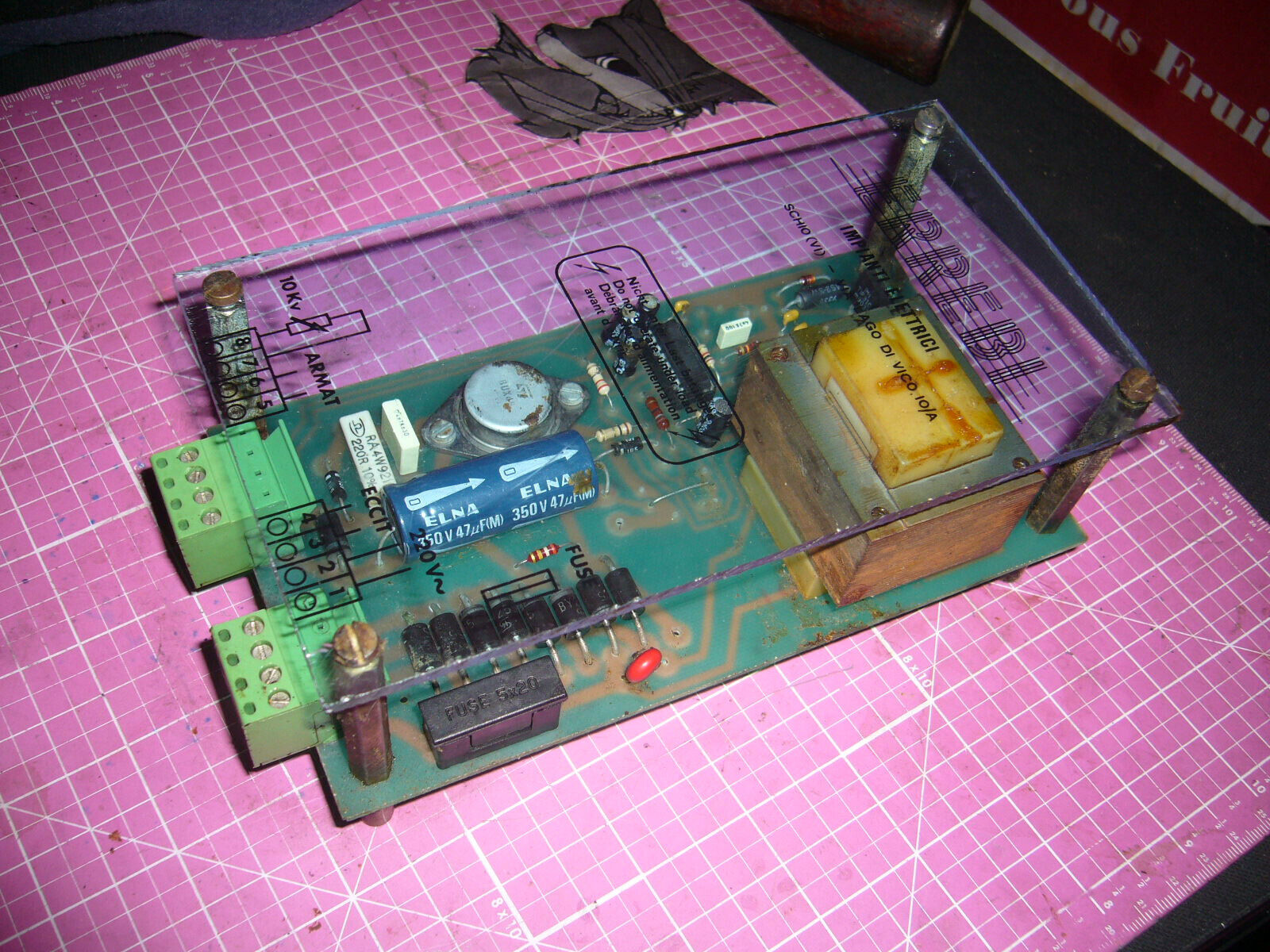

Machine composed by the motor, gear pump, hydraulic cylinder, manual valve, relief valve, cylinder, hopper, and other components.Fill the dough inside the plane, the motor drives the hydraulic cylinder to press and push the dough through mould, extrusion by mold.

Note

1.Single-phase motor in motion will produce electrostatic, before using this machine should be connected to ground.

2.Every time before starting, check each part screws should be tightened, are not allowed to have loose phenomenon.

3.Bearings should be lubricated well, do not running with lack of lubrication oil.

4.Hopper should be put in place, the coupling nut, nut should be tight, no loose.

5.Power supply, wires, plugs, electrical components shall be no damage, no leakage phenomenon, ban on before inspection.

6.

(1)The hydraulic cylinder should be driving according to the directions.

(2)The machine running smoothly without abnormal phenomenon.

(3)Cut the dough into appropriate size pieces, set aside.

(4)When putting the dough, not into too deep, in case of pressure.

(5)Do not put dry flour in Dough barrels,in case the machine overload operation then

cause

motor burn out;Avoid long idling.